Product Description

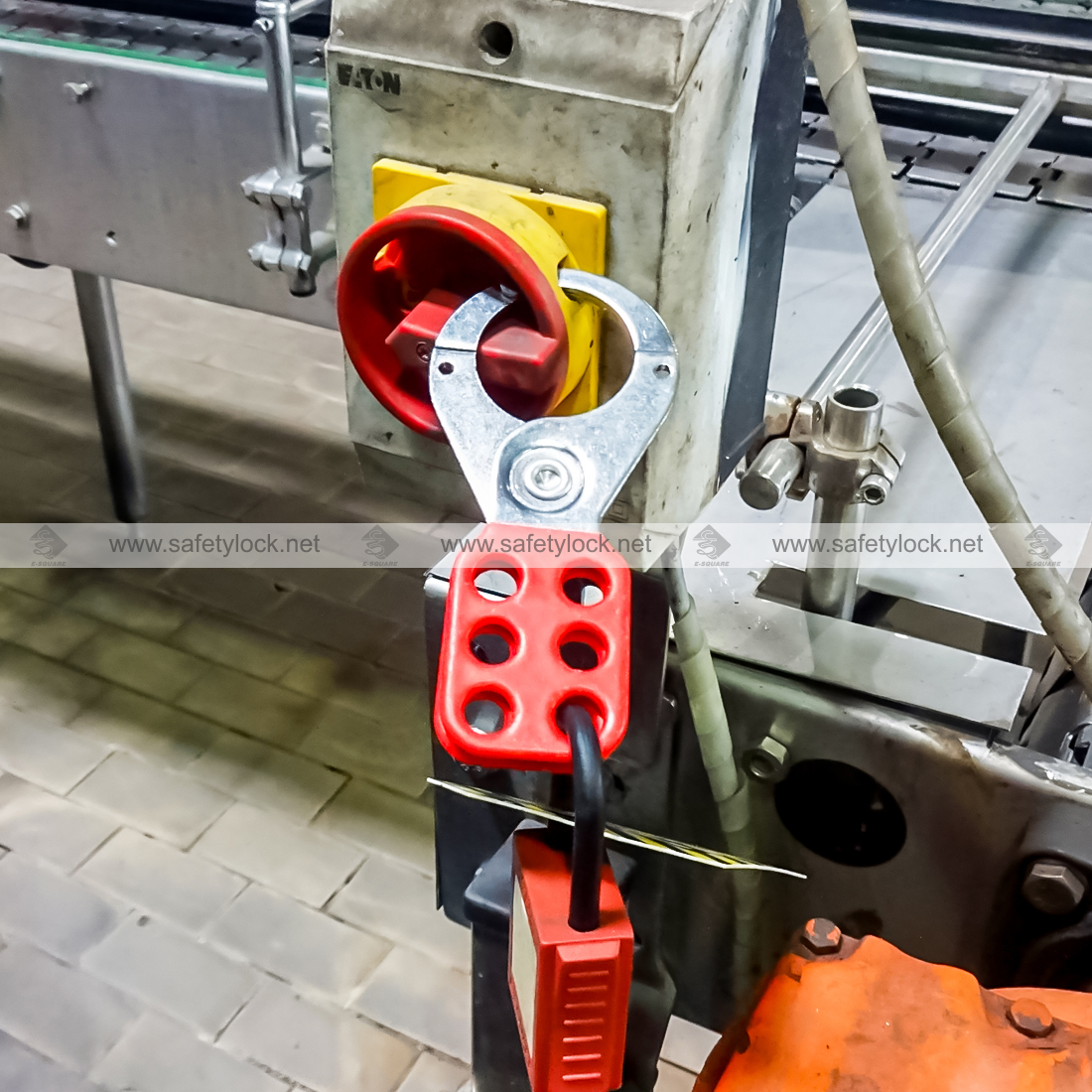

- The First Lock design simplifies the lockout process by highlighting the primary lock placement, reducing confusion and enhancing procedural compliance.

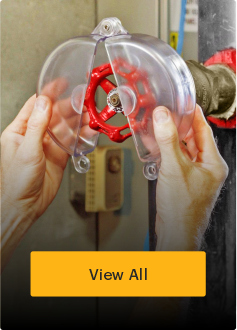

- Made entirely of 304 stainless steel, ideal for harsh environments where corrosion and durability are concerns.

- Supports up to six padlocks, with the first lock position marked for easy identification by all team members.

- Its 25mm jaw size and design make it perfect for securing standard industrial devices, from valves to switches.

- Meets global safety standards, ensuring a reliable lockout solution for maintaining a safe work environment.

Explanation of First Lock Design and Its Benefits:

The “First Lock” design is an innovative feature in these stainless-steel lockout hasps. It includes a specially designated hole for the first padlock used during a lockout procedure. This design ensures that the initial lock, which sets the standard for the subsequent locks, is clearly visible and accessible. This is particularly beneficial in environments where multiple workers need to secure equipment, as it:

- Enhances Safety: Ensures that the critical first lock is easily identifiable, reducing errors and enhancing procedural compliance.

- Promotes Efficiency: Streamlines the lockout process by clearly defining the sequence of lock application, which can speed up both application and removal during maintenance or emergency stops.

- Improves Communication: Acts as a visual cue that informs all personnel involved about the status of the lockout, facilitating better coordination and safety awareness.

These benefits make the First Lock design an excellent choice for industries aiming to improve their safety protocols and ensure compliance with lockout/tagout regulations effectively.