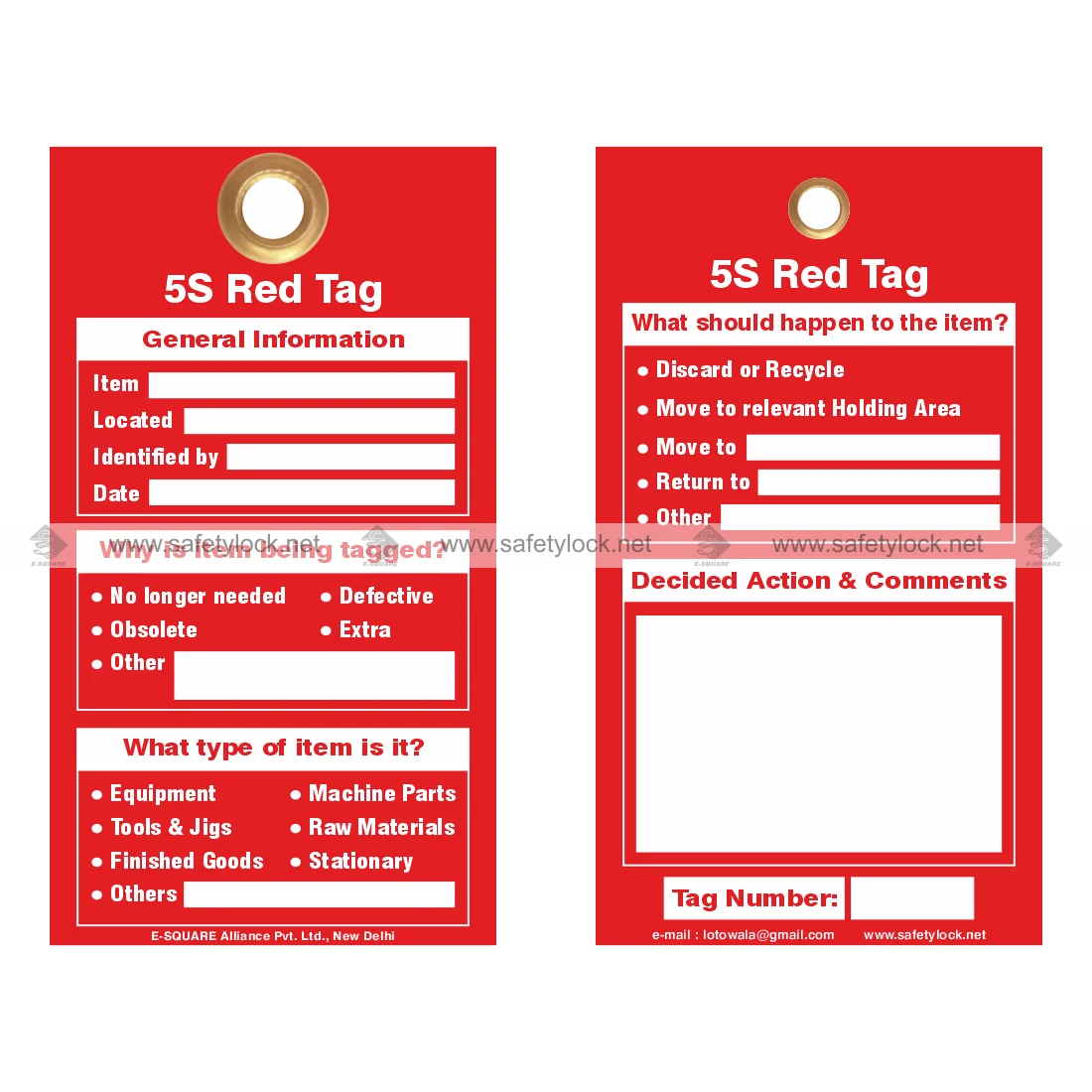

5s Products

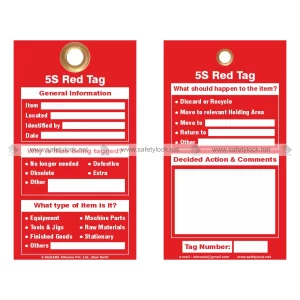

A cluttered, untidy workplace often leads to accidents, production delays, and even fatalities, all of which disrupt operations and have a negative impact on a firm. A 5s methodology is a five-stage approach for developing the discipline required for significant and continuous improvement while also providing a more structured and productive workplace. This five-step technique involves – Sort, Set in Order, Shine, Standardize, and Sustain. The 5S concept encourages operators to enhance their entire work environment and eliminate waste.

Showing 1–8 of 83 results

Our New Catalogue

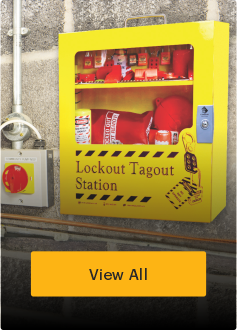

Discover the widest range of lockout tagout products available globally.

Enter your email below and get a link to download your digital copy.

Address

- E-Square Alliance Pvt. Ltd.

512, New Delhi House, Barakhamba Road

New Delhi - 110001, India - +91 8750 333 102 (Call)

- +91 8750 333 102 (Whatsapp)

- +91 8750 175 175 (Sanjay)

-

LOTO@safetylock.net

SALE@esquare.info

Contact Us

Worldwide Delivery

Via Fastest Mode AvailableWide Choice

1600+ Items availableCustomisation Available

No MOQ for standard productsDirect Technical Support

From our expert LOTO EngineersAny Questions?

In Lockout Tagout, every detail counts. Let’s discuss yours.

Hi! I'm Pyush, the Technical Director at E-Square

Please write to me here if you have any questions or require any kind of assistance. We will get back with an answer ASAP !