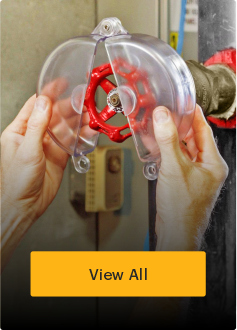

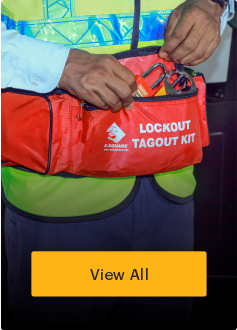

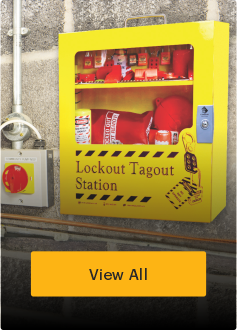

How to Improve Lockout Tagout Efficiency with Proper Equipment and Devices

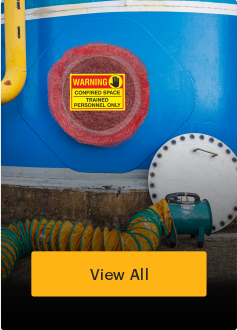

Spread the loveLockout Tagout is a fundamental procedure for ensuring workplace safety during dangerous machine operations like maintenance or servicing. Specifically designed to safeguard authorised employees from hazardous energy releases like electrical, hydraulic, pneumatic or mechanical, the Lockout Tagout program is the ultimate defence from unexpected and accidental start-ups, providing a safe and accident-free workplace […]