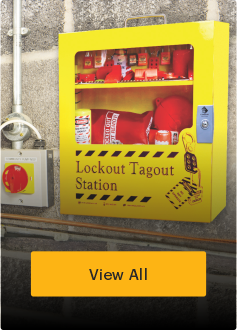

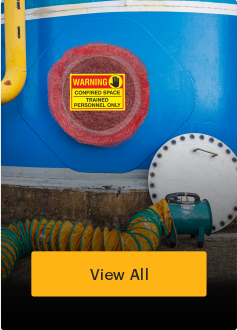

Optimizing Safety and Efficiency with Alternative Lockout Tagout Measures

Spread the loveIf you work in the safety profession or with heavy machinery, you’ve probably heard of Lockout Tagout. This guideline has significantly reduced the frequency of fatalities and injuries in all general industrial workplaces. Although there have been various adjustments and enhancements to how we implement OSHA 1910.147 over the years, the regulation has […]